Mumyoi is the name of the clay containing iron oxide produced in the neighbourhood of the Sado gold and silver mine. Mumyoi-yaki, or Mumyoi ware, is a type of ceramic made by firing clay creations at a high temperature. It is extremely solid, and produces a clear, metallic sound when flicked with a finger. The more it's used, the more it glows.

Mumyoi is the name of the clay containing iron oxide produced in the neighbourhood of the Sado gold and silver mine. Mumyoi-yaki, or Mumyoi ware, is a type of ceramic made by firing clay creations at a high temperature. It is extremely solid, and produces a clear, metallic sound when flicked with a finger. The more it's used, the more it glows.

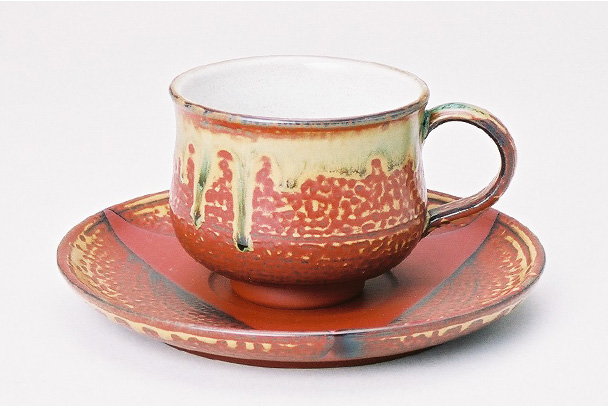

The craft of Mumyoi ware features a unique process: The surfaces of the half-dried objects are pressed with a spatula so they are strengthend and become smoother. This process is called "nama-migaki" (literally: raw polishing). The surfaces are polished again with sand (sand polishing) after firing.

After being put through a 200-mesh sieve* in water, the clay becomes tiny fine particles, which shrink by 30 per cent when fired. This is why the ware is extremely solid, and produces a clear, metallic sound when flicked with a finger, and why the more it's used, the more it glows.

The Mumyoi clay is thought to have medicinal properties, and is beneficial to relieve palsy, stomach and bowel disorders, burns and to help stop bleeding.

At this workshop, we pursue expressions of traditional Mumyoi ware styles, as well as the beauty of colour variations that are achieved with the climbing kiln, and glazes made by mixing natural rocks from Sado and wood charcoal. Mumyoi ware attracts people's attention because it can enhance the taste of drinks, such as tea, sake, beer and coffee.

*This process is called "suihi," or water filteration. By filtering the clay particles, sand and impurities are removed.